What have we done?

Brown University (2005 – 2008)

Doug Wen under WM Group Engineers was the principal-in-charge and project manager for the campus utilities renewal and upgrade project that started in 2005 and lasted 3 years. Work included master planning and engineering design for numerous projects as follows:

Campus High Temperature Hot Water Distribution Network

Replaced the entire direct buried piping for the distribution of high temperature hot water (340 degree F) throughout the campus; work required comprehensive pipe stress analysis, coordination with public utilities, commissioning and field services.

Central Heating Plant

Installed new industrial SCADA system for boiler mater and burner controls; replaced #6 fuel oil heater set and boiler plant auxiliary equipment; provided variable frequency drives for high temperature hot water pumps; performed cogeneration feasibility study which is approved by the University management and currently in validation stage; expanded the heating plant into a district cooling plant serving the athletic campus

Campus District Cooling Systems

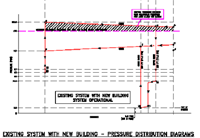

Performed a master plan study that recommended dividing the campus into seven cooling districts. Designed Core Campus district cooling plant (3,000 tons); developed control sequence to operate the Core Campus, Life Science and BioMed chiller plants as a virtual central chilled water system.

Campus Power Distribution (by Holtaway)

Performed master plan and engineering design to upgrade and improve the reliability of the campus power distribution system that comprises 35 kV, 11 kV and 5 kV switchgear and substations.

Brown University – Rockefeller Library District Cooling System (2009)

The Rockefeller Library chilled water plant utilizes all primary pumping and is experiencing low system delta T, inefficient chiller operation and excessive pumping. There have been conditions that require three chilled water pumps running while only one chiller was operational in order to meet the system DP requirement. The buildings connected to the Rockefeller Library chilled water system include a variety of HVAC systems. W-engineering identified several Energy Conservation Measures (ECMs) that would improve the overall performance of the chilled water system and reduce energy costs. The study received approval from Brown University and remedial measures are currently under construction.

Brown University – MacMillan Hall District Cooling System (2009)

The MacMillan chilled water district comprises three interconnected chiller plants MacMillan, Watson CIT and Bio-Med. These plants are not currently setup to operate together and Brown University has concerns about the reliability of the Watson CIT plant which serves Data Centers critical to the operation of the University. The plants are a mix of Primary/Secondary pumping and constant flow all primary pumping designs. W-engineering provided recommendations to convert the system into a true virtual central system which would improve the reliability and energy efficiency of the district cooling system.

Pearl of the Emirates District Cooling Plant (2008)

W-engineering and Holtaway provided mechanical and electrical engineering services to an EPC contractor for the construction of a 90,000 ton district chiller plant (70,000 ton by mechanical cooling and 20,000 tons from chilled water storage) in Abu Dhabi, UAE. Work included conceptual design report, detailed engineering design drawings and specifications, procurement assistance for major equipment, short-circuit analysis (22 / 11 / 3.3 kV), and hydraulic analysis of chilled water distribution network.

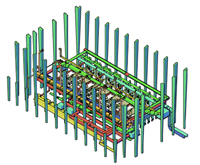

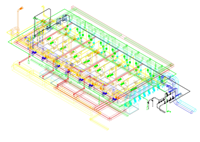

Al Shams District Cooling Plant (2007)

Doug Wen under WM Group Engineers was the principal-in-charge and project manager for the design of three 40,000 ton district chiller plants in Abu Dhabi, UAE. Holtaway was responsible for the electrical engineering design. These chiller plants employ all-primary variable flow pumping to deliver chilled water to the end users, which is a pioneer design in the region. Work included conceptual design report, detailed engineering design drawings and specifications, procurement assistance for major equipment, short-circuit analysis (11 / 3.3 kV), and hydraulic analysis of chilled water distribution network. Your browser may not support display of this image. W-engineering prepared 3-D design drawings for one of the chiller plants. The 3-D drawings ensured no conflicts among piping, ductwork and cable trays.

Royal Hobart Hospital (2008)

Doug Wen under WM Group Engineers was the principal-in-charge and project manager for the utility master plan study for the green field hospital in Tasmania, Australia. The study included computer modeling and comprehensive life cycle cost analyses on applicable central plant and cogeneration options. The study also included sensitivity analyses that account for utility rate fluctuations and carbon emission credits.

New York Presbyterian Hospital (2004)

Doug Wen under WM Group Engineers was the project manager for the cogeneration feasibility study project for the NYPH downtown facility at 70th Street in New York. The project was done in conjunction with Holtaway. The study used computer modeling of the combined heat and power plant facility to simulate plant operation. Recommendations were made based on life cycle cost analysis in conjunction with sensitivity analysis. Holtaway performed comprehensive short-circuit analyses and held extensive discussions with Con Edison engineers to resolve the fault current limitation issues of the Con Edison substation. The study received approval from NYPH management and the project is currently under construction.

Yale University (2003 and 2008)

Doug Wen under WM Group Engineers was the project manager for the expansion of the high pressure steam distribution system in the Science Hill campus that comprised direct buried conduit piping. Doug Wen employed remote trapping concept and eliminated the need for manholes at the low points. A new tall building to be connected to the central chilled water system of Sterling Power Plant at Yale University would likely increase the system working pressure beyond the level of comfort. Plate and Frame heat exchangers were considered to isolate the new building from the central chilled water system. W-engineering applied the split-expansion tank theory to successfully reduce the system working pressure and eliminate the need for heat exchangers.

Borgata – Hotel Casino and Spa (2009)

Borgata receives medium temperature hot water and chilled water from a third party district energy plant and has suffered from the low delta T syndrome. As a result, the resort was paying heavy penalty fees to the chilled water supplier. W-engineering under a retro-commissioning project reviewed the chilled water system and provided recommendations of corrective actions.

Atlantic City Convention Center (2009)

The Atlantic City Convention Center receives hot water and chilled water from a third party supplier and has been paying over $1.75M for the heating and cooling energy. In an attempt to reduce the energy expenditure, W-engineering provided retro-commissioning services that included reviewing the original design and operation of the heating and cooling systems, and identifying opportunities to improve the energy efficiency. Recommendations are based on life cycle cost analysis.

Amtrak – New York Penn Station Chiller Plant Replacement (2009)

W-Engineering completed the design of a new chiller plant for the Amtrak facility at the Penn Station in New York City. The project entailed installation of three 1300 ton chillers complete with pumps cooling towers in the existing services building on W. 31st Street, and demolition of the existing chiller plant in Penn Station. Due to the year round cooling requirement, the design included detailed phasing to minimize the down time. Hydraulic calculation for the entire chilled water distribution system was performed to streamline the piping network and pump sizing. Construction will start in 2010.

Columbia University (2008 - present)

W-engineering is retained as the Owner’s engineer by Columbia for the renovation and upgrade of the central chilled water system at the Morningside campus. The project entails master plan study of the entire chilled water system and expansion of the existing central chiller plant. Two 2800 ton chillers will be installed in the Old Power House and new cooling towers will be installed on Fairchild building roof. The project is scheduled to be completed in June 2011.

Moses Brown School, Providence RI (2009)

The existing central heating system at Moses Brown supplies hot water and steam to 16 buildings on campus. Built over 60 years ago, the system is in need of major renovation. A few newer buildings have been provided with local boilers. W-engineering is commissioned to perform a master plan study on the heating system. The study will provide the School with recommendations to continue with existing central heating system or convert to local heating boilers.

Masdar Project, Abu Dhabi, United Arab Emirates (2008/9)

Masdar is a planned city in Abu Dhabi that will rely entirely on solar energy and other renewable energy sources, with a sustainable, zero-carbon, zero-waste ecology. W-engineering is a member of an EPC team tendering for the Phase I Central Station project. Hot water at 90OC, 120 OC and 180 OC is generated with solar collectors, and is used for absorption chillers, and regeneration of liquid and solid desiccant. Chiller plant comprises electric motor driven chillers, single effect and double effect absorption chillers, and chilled water storage. The phase I project also includes reticulation of chilled water, medium temperature hot water and liquid desiccant in a combination of direct buried, tunnel and aboveground pipelines.

Kai Tak Airport Redevelopment, Hong Kong (2009)

W-Engineering was part of a design/build team for the tendering of the Redevelopment of Kai Tak Airport project in Hong Kong. The project entailed two district cooling plants with combined capacity of 85,000 tons. Sea water from Victoria Bay was used for condenser water at the chillers. W-Engineering was responsible for the design of the district cooling plants and seawater pumping stations.